Advanced single-phase motors are designed to be uses where larger single-phase motors are needed and/or where the distribution has a weak short-circuit level, because they use technologies that overcome the traditional limitations of conventional single-phase induction motors — especially for high power (tens of HP) and weak rural grids. Please visit Selecting the Right High Horsepower Drive for Rural Settings for more information.

Here are the main reasons.

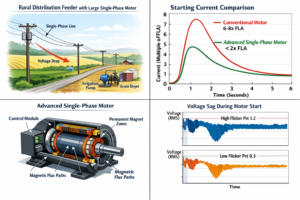

1️⃣ Very Low Starting Current (Key Difference)

Conventional single-phase motors:

- 6–8 × full-load current (FLA)

- Large voltage sag on long feeders

- Severe flicker

- Utility complaints

Advanced designs:

- Typically 1.5–2.5 × FLA

- Grid-friendly starting

- Minimal voltage dip

This is usually achieved by:

- Electronic control of magnetization

- Rotor field manipulation

- Soft-start behavior built into the motor

This single feature alone makes them “advanced”.

2️⃣ Special Rotor Technology (Not Standard Induction)

Many high-power single-phase motors use:

Written-pole / programmable rotor field

or

Permanent-magnet assisted rotor

or

Electronic commutation assistance

These allow:

- High starting torque with low current

- Stable operation over load range

- High efficiency

A normal single-phase induction motor cannot do this efficiently at high power.

3️⃣ High Efficiency Comparable to 3-Phase Motors

Traditional single-phase motors:

- Lower efficiency

- Poor power factor

- High losses

Advanced motors:

- Efficiency close to premium IE3 / NEMA Premium

- High power factor (often >0.95)

- Lower heating

This is a major engineering improvement.

4️⃣ Built-In Power Electronics

Many designs include:

- Controller module

- Smart starting algorithm

- Electronic phase shifting

- Protection and diagnostics

So the motor behaves partly like:

Motor + soft starter + controller in one unit

5️⃣ Ability to Reach High Horsepower on Single Phase

Historically:

- Single-phase motors rarely exceeded ~10–15 HP reliably

Advanced motors:

- 25 HP

- 50 HP

- 75 HP+

- Even 100 HP in some cases

This is a huge technological step for rural electrification.

6️⃣ Power Quality Friendly (Important for Your Field)

From a PQ perspective they:

- Reduce voltage sag

- Reduce flicker (Pst / Plt)

- Reduce feeder disturbance

- Lower inrush harmonic distortion

- Improve system stability on weak grids

That’s why utilities often prefer them over phase converters.

7️⃣ Better Torque Characteristics

They provide:

- High locked-rotor torque

- Smooth acceleration

- Good pull-up torque

- Stable speed regulation